Germicidal Ultraviolet Lamps

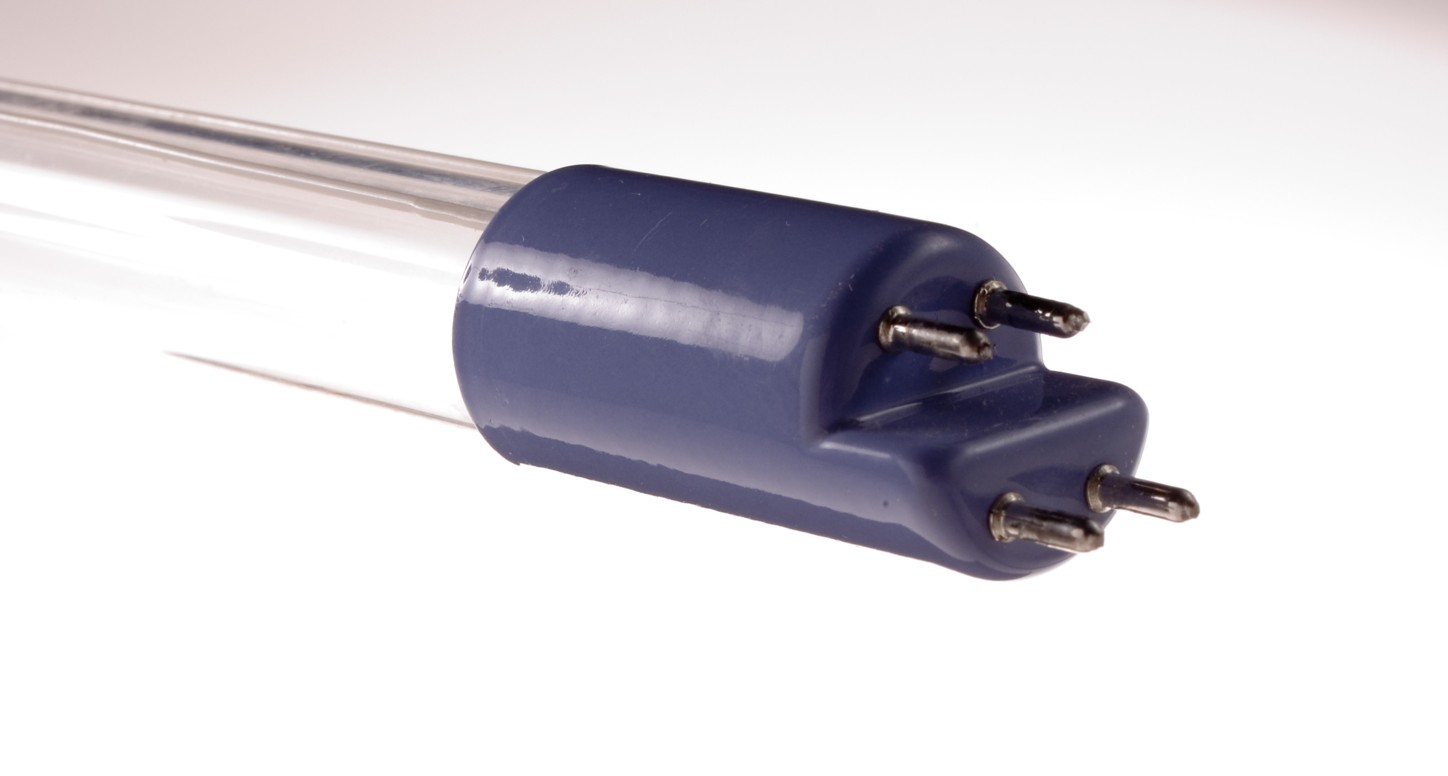

Ultraviolet germicidal lamps are divided into 3 groups: Standard low pressure, low pressure high output (HO) and low pressure amalgam. Germicidal ultraviolet lamps require mercury to change phase from liquid to the vapour phase in order to form a plasma or discharge. Low pressure ultraviolet lamps are essentially the same as standard fluorescent lighting that we are all familiar with. When mercury is excited into the vapour phase it emits ultraviolet light at a wavelength of 254nm. A fluorescent lamp has an internal coating of phosphor, which converts ultraviolet light to white light, which of course is very useful for internal lighting. A germicidal lamp does not have the phosphor coating so the output will be only 254nm (UVC) light. By removing the phosphor coating and making the lamp tube from the right grade of quartz, the lamp will transmit ultraviolet light. Normal glass products will absorb the ultraviolet light and the net transmittance of uv is zero.

Low Pressure Ultraviolet Lamps

The vapour pressure of a normal low pressure ultraviolet lamp is governed by the temperature of the mercury: If the temperature falls, the irradiance or the amount of uv light transmitted falls. An amalgam ultraviolet uv lamp does not contain liquid mercury like a standard low pressure mercury discharge lamp. In this type of ultraviolet UV lamp, the mercury is alloyed with the principle metal Indium forming an amalgam of the two metals. The amalgam is not dispersed throughout the lamp as free mercury like a normal ultraviolet low-pressure lamp, but instead it is placed and fixed at two condensation points along the axis of the quartz tube. This provides the optimum mercury vapour pressure at higher lamp temperatures, normally 80-85C, and the amalgam bead or blob acts as a pressure regulator, releasing mercury into the vapour if the pressure falls, or conversely, absorbing mercury if the pressure rises. The result is that the net output of ultraviolet light remains constant. This is the critical point. The benefit is when the ambient water temperature fluctuates, either rises or falls, the amalgam lamp is not effected by outside temperature and uv output or fluency, remains constant over a large temperature range. This is particularly useful in Europe where water temperature can be near freezing. Low pressure lamps would either be inefficient or even cease to function at this temperature because the liquid mercury would not evolve from the liquid phase into the vapour phase. Water temperature will fluctuate in a typical WWTP in all countries, factors due to weather, flow rate, turbity, surrounding catchment material etc. The amalgam ultraviolet lamp will operate at a constant ultraviolet output irrespective of the water temperature. Maintaining a constant output over a large ambient temperature range is critical to the performance of a UV system because disinfection rates are dependant on uv the absolute value of absorbance into the microogansims. If the transmittance of the ultraviolet lamp falls, kill rates will decrease dramatically.

Ultraviolet Lamps In Waste Water Treatment

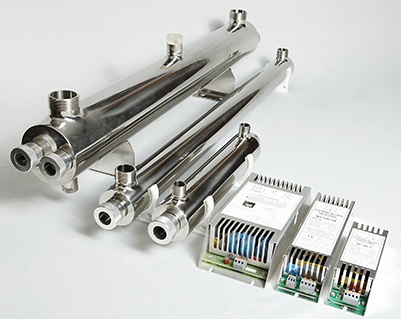

In a typical wastewater treatment ultraviolet uv system, the amalgam lamp is placed in a quartz sleeve, installed in banks of multiple lamps and controlled by variable power supply or ballast, often two lamps per ballast. The quartz sleeve insulates the lamp from the water, allowing the lamp to operate at the optimum temperature of 80- 85C. The ultraviolet lamp temperature will remain independent of the ambient water temperature which could be near freezing. Important to the design of the system is the diameter of the lamp and internal diameter of the quartz sleeve. Variable output ballasts allow the operator to adjust the power of the lamp according to the operating conditions, specifically water flow and turbidity. By lowering the power input to the lamp via the ballast, there is a small benefit of saving on power costs, but will also prevent the slow moving or stagnant water from increasing in temperature, possibly compromising the lamp itself. A high water temperature due to slow or stagnant water flow is not the ideal condition for a 250W amalgam lamp. The lamp could overheat and fail. Failure can be via a number of mechanisms, one of which is when the amalgam separates from the quartz envelope becoming lose inside the lamp.If this happens, the output will be irregular or low. The lamp should be installed so the amalgam points are at the bottom or on the side not on the top.

Amalgam lamps are best suited to high flowing water treatment systems where high fluency rates are required, often built into multi-lamp reactor units. Many equipment manufactures including Trojan and Wedeco have been using amalgam lamps in their uv units for many years. Wastewater treatment and sewage treatment systems that have slow flowing water, or water that remains still for long periods of time are not suited to amalgam lamp systems because the lamps will become too hot inside the quartz sleeve. If the lamp exceeds 130C, the amalgam will melt, and possibly separate from the quartz tube. Municipal WWTPs and STPs are the best application for uv amalgam lamps because the water flow is normally constant. Even though amalgam lamps cost more than normal low pressure lamps, the higher ultraviolet output of amalgam lamps does result in a good return in the long term because less lamps are required than standard if lamps are used and they have much they have longer lifetimes than medium pressure lamps. Longer lamp lifetimes are available due to the inherent design of the lamp itself, the advances in technology for electrode design and internal protective coatings. Lifetimes of up to 16000 hours are often achieved.

Lamp Lifetime

Amalgam ultraviolet lamps are best suited to high flowing water treatment systems where high fluency rates are required, often built into multi-lamp reactor units. Many equipment manufactures including Trojan and Wedeco have been using amalgam lamps in their ultraviolet disinfection systems units for many years. Wastewater treatment and sewage treatment systems that have slow flowing water, or water that remains still for long periods of time are not suited to amalgam lamp systems because the lamps will become too hot inside the quartz sleeve. If the lamp exceeds 130C, the amalgam will melt, and possibly separate from the quartz tube. Municipal WWTPs and STPs are the best application for uv amalgam lamps because the water flow is normally constant. Even though amalgam lamps cost more than normal low pressure lamps, the higher ultraviolet output of amalgam lamps does result in a good return in the long term because less lamps are required than standard if lamps are used and they have much they have longer lifetimes than medium pressure lamps. Longer lamp lifetimes are available due to the inherent design of the lamp itself, the advances in technology for electrode design and internal protective coatings. Lifetimes of up to 16000 hours are often achieved.