ULTRAVIOLET DISINFECTION-WHAT IS IT?

All you need to know about uv disinfection

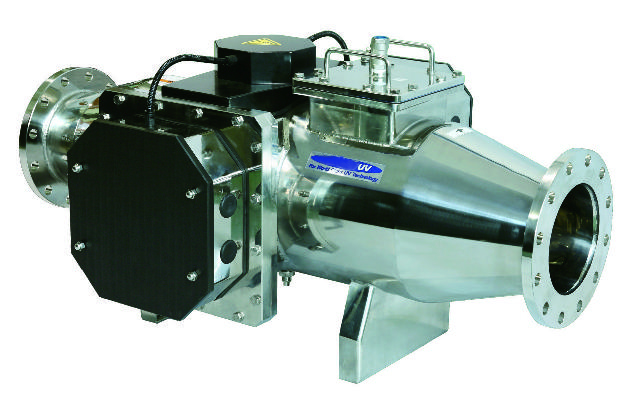

Ultraviolet disinfection has many advantages over alternative methods. Unlike chemical biocides, Ultraviolet disnfection and sterilization techniques do not introduce toxins or residues into process water and does not alter the chemical composition, taste, odour or pH of the fluid being treated. This is one of the most important aspects of all ultraviolet disinfection systems. This feature is especially important in the food and dairy industry where the chemical dosing of incoming process water can compromise flavours and changes the physical chemical properties of the food products. Ultraviolet UV treatment can be used for primary water disinfection or as a back up for other water purification methods such as carbon filtration, reverse osmosis or pasteurisation. As UV has no residual effect, the best position for a treatment system is immediately prior to the point of use. This ensures incoming microbiological contaminants are deactivated and there is a minimal chance of post-treatment contamination. Many users install UV systems after filter beds and storage tank outlet valves to reduce the likelihood of contamination from these sources. A typical UV disinfection system consists of an ultraviolet UV lamp housed in a protective quartz sleeve, which is mounted within a cylindrical stainless steel chamber. The liquid to be treated enters at one end and passes along the entire length of the chamber before exiting at the other end. Virtually any liquid can be effectively treated with UV, including mains water, filtered process water, milk, sugar syrups and effluent.

ULTRAVIOLET DISINFECTION SYSTEMS

Ultraviolet disinfection systems have many uses in commercial, industrial and domestic applications.Ultraviolet lamps, germicidal bulbs and ultraviolet disinfection lamp are widely accepted in applications such as:

- Water purification, UV disinfection and sterilisation for domestic and industrial water treatment.

- Domestic, commercial and industrial wastewater treatment

- Municipal sewage and wastewater treatment

- Aquaculture, fish farming, oyster farming water treatment, disinfection and purification

- Disinfection and sterilisation of potable drinking water

- Disinfection and sterilisation of industrial process water

- Air purification in ducting of factories, food-processing plants, nursing homes, and hospitals

- Surface disinfection, food conveyor sterilisation

SUITABILITY OF UV TREATMENT

If you are using hazardous chemicals such as chlorine for your disinfection and sterilisation, the true costs of using those chemicals on site can be alarming – for example, purchase, storage, environmental compliance, workplace health & safety compliance, staff training, accidents and spills, disposal, or costs of removing residual chlorine from disinfected waters for re-use. And that is only the costs to your individual business – what about the life cycle environmental cost of that chemical – such as raw materials, manufacturing energy, transport, and disposal – for which we all bear a huge responsibility? Taking the above factors into consideration, it isn’t hard to see why more and more businesses are choosing UV disinfection systems, especially with the following benefits:

Many Advantages of UV Disinfection Systems

- No known toxic by-products;

- No residual odour in final water system

- Rapid disinfection (seconds, rather than minutes)

- No hazardous material storage

- Minimal space for equipment and treatment chamber

- Removes some organic contaminants

- Little or no environmental impact, except for disposal of obsolete equipment.

- Mercury is recycled

ULTRAVIOLET DE-ACTIVATION

Ultraviolet disinfection de-activates most common pathogens such as Cryptosporidium or Giardia and some bacterial pathogens. The technology uses ultraviolet light from a mercury arc lamp to destroy an organism’s genetic material (DNA, RNA) and prevent reproduction. Basically, the wastewater is directed through a sealed chamber that exposes it to ultraviolet rays. The characteristics of water that may reduce the effectiveness of ultraviolet treatment are: water hardness, pH, total suspended solids, turbidity, humic materials and iron. So it is important to investigate whether the technology can be applied to your wastewater, and whether pre-treatment is required.

WHAT IS ULTRAVIOLET LIGHT

Light is important to almost all forms of life. The human eye sees only a small fraction of the colours of light. From this we are only interested primarily in the light with wavelengths beyond the violet end of the light spectrum or the ultraviolet range. The usual wavelength range in photochemical reactions is between 100-1000nm. Photons with wavelengths longer than 1000nm do not have enough energy to cause chemical change when absorbed. The ultraviolet photochemical range is divided up into 3 groups:

UVA 315-400nm |

UVB 280-315nm |

UVC 100-280nm |

|---|

The wavelength of ultraviolet that causes this effect is rare on Earth because the outer atmosphere absorbs it. Very useful indeed otherwise life on earth would be compromised. Using ultraviolet light sterilisation, in certain applications like circulating air or water systems, creates a deadly effect on microorganisms such as pathogens, viruses and moulds that are in these environments. Coupled with a filtration system, ultraviolet light disinfection and sterilisation techniques can remove harmful microorganisms from these environments. The application of ultraviolet light sterilisation has been an accepted practice since the mid-20th century. It has been used primarily in medical sanitation and sterile work facilities, however now it is commonly employed to sterilise and purify drinking water, recycled water and treat wastewater sewage. Ultraviolet systems are commonly employed in tertiary wastewater and sewage treatment plants today. In an increasingly regulated and safety-conscious market, the water and food industry has to meet ever more stringent standards of quality.

UVC RADIATION

The three sub ranges are connected to the human skin’s sensitivity to ultraviolet light. UVA causes suntanning, UVB sunburning, may cause injury to the skin and UVC is dangerous to the extent that it will mutate RNA and DNA. Hence UVC light must be treated with utmost care. UVC is the prime wavelength for germicidal treatment, extremely effective in deactivating and killing bacteria, moulds and viruses. Ultraviolet light irradiation is a disinfection process and sterilisation method that uses ultraviolet UV light at sufficiently short wavelength to break down microorganisms. It is used in a variety of applications, such as food, surface, air and water purification. Ultraviolet light has been a known mutagen at the cellular level for more than 100 years. Ultraviolet light irradiation utilises the short wavelength of ultraviolet UV that is harmful to forms of life at the atomic level. It is effective in destroying the nucleic acids in these organisms so that their DNA is disrupted by the UV radiation, which is a form of ionising radiation. This removes their reproductive capabilities and/or kills them.

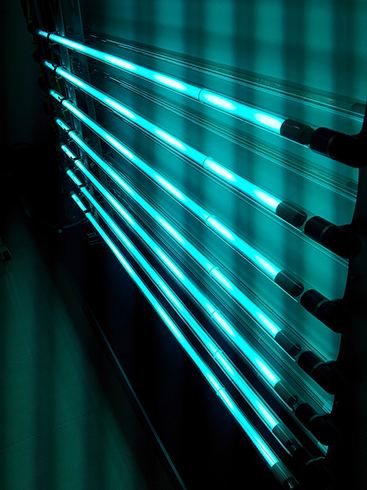

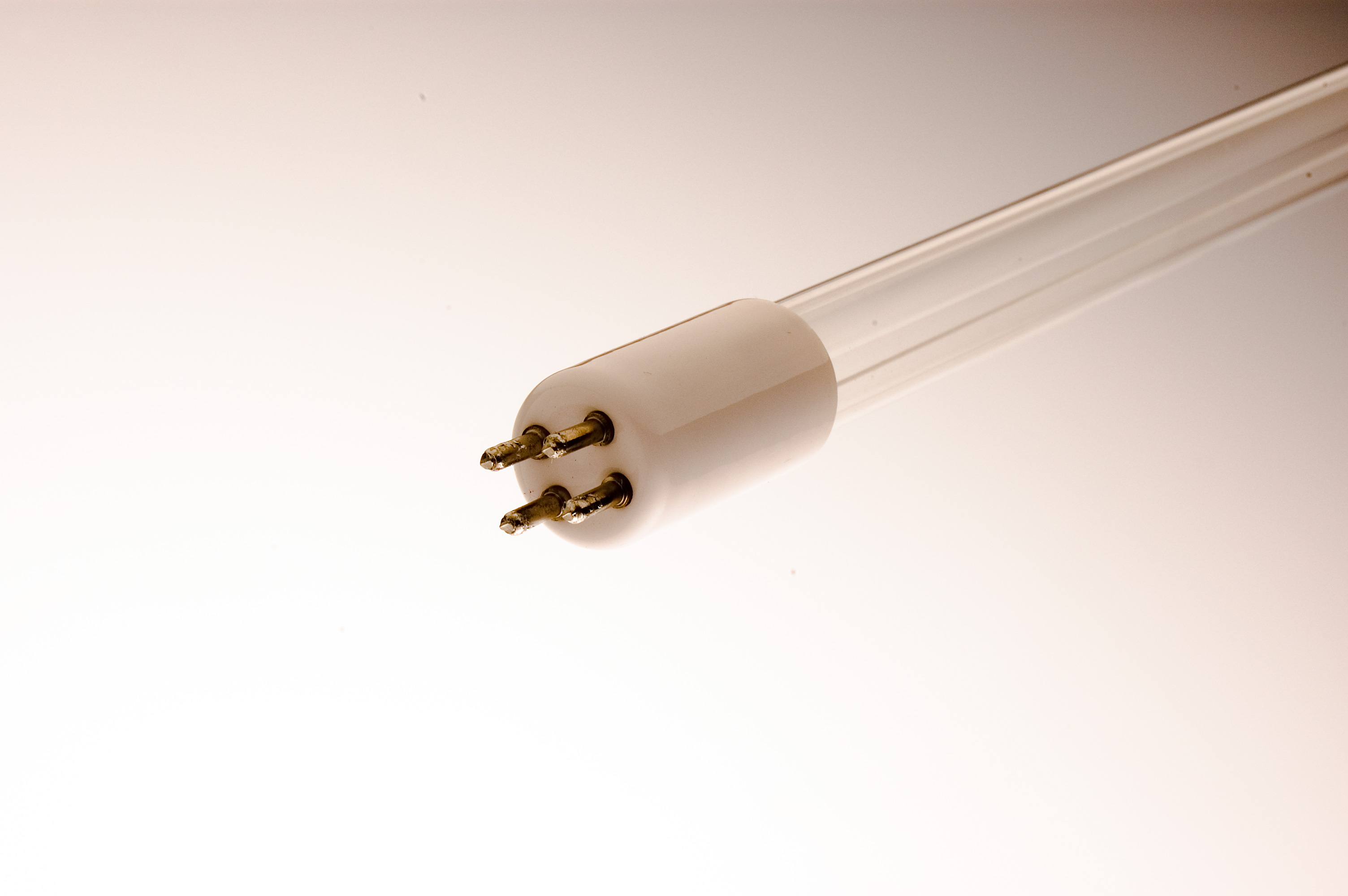

ULTRAVIOLET LAMPS

Microbial growth in water and food products due to contaminated water supplies can cause discolouration, marginal flavours and much shortened shelf life, as well as increasing the risk of infection to consumers and returned product. The threat of contamination is further increased as manufacturers respond to consumer demand for reductions in chemical additives and preservatives. Effective microbial disinfection of process water is therefore crucial and essential. A non-chemical method of disinfection, which is gaining increasing acceptance, is ultraviolet UV disinfection using ultraviolet quartz lamps. Ultraviolet UV kills known food organisms that will spoil, including bacteria, viruses, yeasts and moulds. It is a low maintenance, environmentally friendly technology that eliminates the need for chemical treatment while ensuring high levels of disinfection.

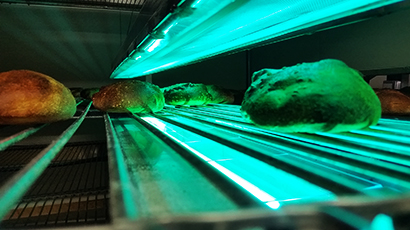

ULTRAVIOLET DISINFECTION OF SURFACES

Ultraviolet light is not only suitable for treating water, sugar syrup but very effective in treating surfaces. Used mostly in the food industry, ultraviolet light can be used safely and cost effective for surface decontamination, particularly on conveyor system. New UV lamp technology using amalgam UV lamps, direct UVC light onto the surface, ensuring there is no cross contamination onto food . UV light is simple and inexpensive compared to other disinfection methods. Wet cleaning can be cumbersome, labour intensive and often not effective. A UV module placed on a conveyor, means the conveyor is treated continuously.