ULTRA-V SERIES UV DISINFECTION SYSTEMS

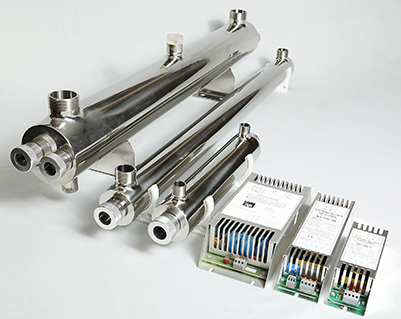

Infralight’s Ultra-V series of ultraviolet disinfection systems are designed to provide many years of service at an affordable price. Treatment chambers are AS304/AS316, polished stainless steel. A complete range of options are available to customise the system according to the parameters of the application. All Infralight uv disinfection and uv sterilization systems are suitable for domestic, farm and industrial applications including pharmaceutical, cosmetics, food, brewing and soft drinks. All uv systems are designed for continuous operation treating cold and hot water. Standard components are used on all Infralight systems: stainless steel chamber, high output uv lamps, residual current detector, lamp failure alarm and lamp hours counter with options for advanced custom designed systems.

- Infralight UV systems are made by Infralight in Australia to AS/NZ 3000/2000 wiring rules

- All Infralight UV systems are supplied with a residual current detector which is required by law.

System Design and Size

|

Ultraviolet disinfection systems are designed acording to several parameters:

In order to achieve the desired level of disinfection, ultraviolet disinfection systems are designed for an end of life dose of 40mJ/cm2. End of life is the amount of hours the uv lamp has been used and is still achieving the desired kill rate. Note, UV dosages must be higher to remove a specific pathogen including viruses, yeasts and moulds. |

|

Relationship Between dose and Kill Based on E.Choli

| Microbial load (cfu/g or cfu/ml) can be expressed as log10 relationship. For example, 100,000 microbes is 5 log, 10,000 microbes is 4 log, 1,000 is 3 log, 100 microbes is 2 log and 10 microbes is 1 log. If the microbe count is reduced from 100,000 microbes cfu/g to 10,000 microbes cfu/g that would be a 1 log reduction (5log-4log). The count is reduced from 100,000 to 32,000 that would be a 0.5 log reduction (5 -4.5 log) etc. UV systems are normally designed for Log 2-log4 removal depending on the specification required. |

|

Standard Models

- Infralight offers standard models in the Ultra-V range.

- The Ultra-V series can be customised and upgraded using standard components.

- Parts are interchangeable between systems.

| Model | UV 300 | UV 400 | UV 1000 | UV 2500 | UV 4000 |

| Flow Rate l/m | 40 | 55 | 130 | 250 | 400 |

| No of UV Lamps | 1 | 1 | 1 | 1 | 1 |

| UV Lamp Watts | 30 | 40 | 100 | 200 | 200 |

| Connection BSP (mm) | 15 | 20 | 40 | 50 | 50 |

| Chamber Material | AS316 SS | AS316 SS | AS316 SS | AS316 SS | AS316 SS |

| Lamp Lifetime | 10000 | 10000 | 10000 | 13000 | 13000 |

| Voltage | 110/240 | 110/240 | 110/240 | 110/240 | 110/240 |

| Circuit Breaker | RCD | RCD | RCD | RCD | RCD |

| IP Rating | 42 | 42 (66) | 54 (66) | 54 (66) | 55 (66) |

| Electronic Ballast | Standard | Standard | Standard | Standard | Standard |

| Lamp Failure Alarm | Standard | Standard | Standard | Standard | Standard |

| Lamp ON indicator | Standard | Standard | Standard | green | green |

| Lamp OFF indicator | red | red | red | red | red |

| UV Sensor | Optional | Optional | Optional | Optional | Optional |

| 4-20mA Output | Optional | Optional | Optional | Optional | Optional |

| Remote Activation | Optional | Optional | Optional | Standard | Standard |

| Off-Delay Relay | Optional | Optional | Optional | Standard | Standard |

| Alarm Contacts | Optional | Optional | Optional | Optional | Optional |

| Mounting Brackets | Standard | Standard | Standard | Standard | Standard |

| Hours counter | Standard | Standard | Standard | Standard | Standard |

| Control Panel | ABS | ABS | ABS | PCS/SS | PCS/SS |

| Cabling | All Cabling inclusive | ||||

Standard Designs

Standardised designs for simple and inexpensive installations.

| Design Flow Rate | Nominal flow rate in l/min with clean water measured at 95% UV transmission. | ||||||

| Connection | All systems are supplied BSP Connectors. Tri clover, BSM, flange available by order | ||||||

| Voltage | Units are rated at 110/ 240V (50/60hz) | ||||||

| Lamp Lifetime | The specified life of the UV lamp to reach 70% of the original irradiance | ||||||

| Residual Current Device (RCD) | All systems are fitted with a residual current device in accordance with Australian and international standards | ||||||

| IP Rating | Standard protection rating is for indoor or undercover installation. Outdoor protection rating (IP65/IP66) is available on all systems | ||||||

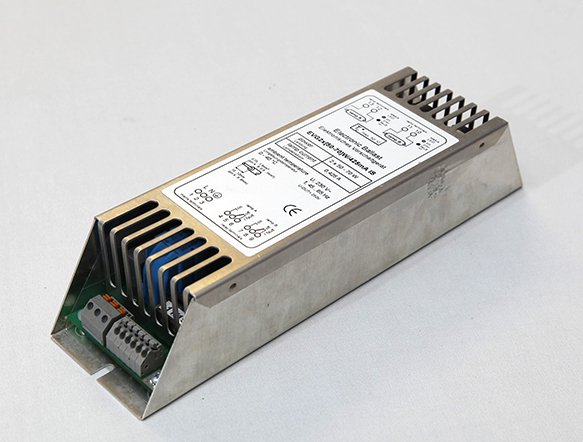

| Electronic Ballast | All systems are installed with an electronic ballast. Electonic ballast offers great reliability, extends lamp lifetime and better lamp starting. | ||||||

| Lamp Failure Alarm | In the event of lamp failure, all systems are equiped with visual and audible alarms | ||||||

| Remote Operation | Allows the user to switch unit either locally or remotely and automatically. Standard on UV1500, 2500 and 4000 systems. | ||||||

| UV Monitor | Optional. UV sensor allows user to monitor UV output. If irradiance falls below set value, alarm will activate | ||||||

| 4-20mA | Remotely monitor UV output with 4-20mA (coupled to UV sensor) or control process as a function of UV output. | ||||||

| Off-delay relay | High outpt systems are fitted with off-delay timers. UV system will switch off after set time to prevent overheating and conserve lamp lifetime | ||||||

| UV Lamp Hours Counter | Operational hours of the UV lamp are recorded and displayed | ||||||

| Alarm Contacts | Remotely monitor UV lamp or trigger remote alarm/shut off valve etc if lamp fails | ||||||

| Control Panel Material | Standard material is ABS and powder coated steel with option for stainless steel. | ||||||